Equipment Brochure

View the latest Duravant equipment brochure.

Solutions

Explore end-to-end automation solutions that increase efficiency, improve quality, and help businesses thrive.

Markets

Learn how we serve industries worldwide with automation expertise tailored to the unique needs of each market.

Our Brands

Explore Duravant’s family of operating companies, united by expertise, shared values, and integrated solutions

View the latest Duravant equipment brochure.

Services

Access a global network of experts delivering full lifecycle support, from installation to optimization.

View latest Duravant Lifecycle Services brochure.

Company

Learn how Duravant unites world-class brands and people to keep essential goods moving smarter, faster, and more reliably.

Explore the latest Duravant brochure.

Pure Performance, Without Compromise.

Our breakthrough automation eliminates the product damage and inconsistency that traditional bakery and snack equipment accepts as unavoidable.

Bakery and snack food manufacturers depend on Duravant automation solutions to handle their delicate products without compromising quality. Our systems manage the complete production process — precise sortation, gentle conveying, perfect seasoning, protective packaging and case packing — to protect inventory while preserving the experience of enjoying a perfect snack.

From Key’s optical sorting and vibratory conveying to PPM’s seasoning, coating, and frying systems, our solutions deliver standardized taste quality and gentle handling for premium bakery and snack operations.

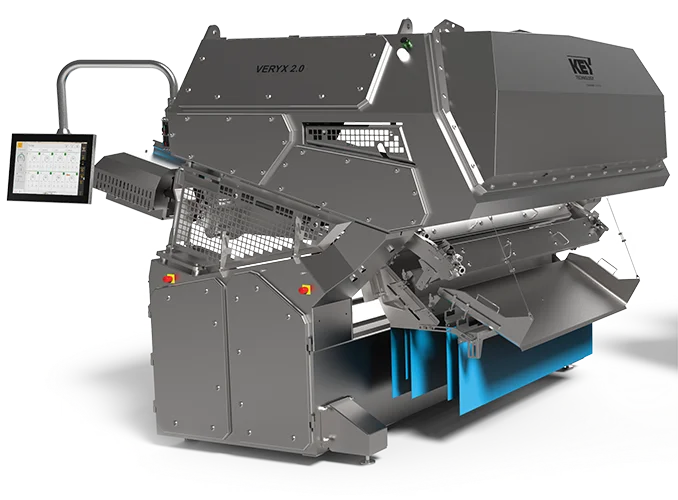

Key Technology delivers precise digital sorting with VERYX and COMPASS platforms that maximize yield and quality while providing real-time data analytics for continuous process optimization.

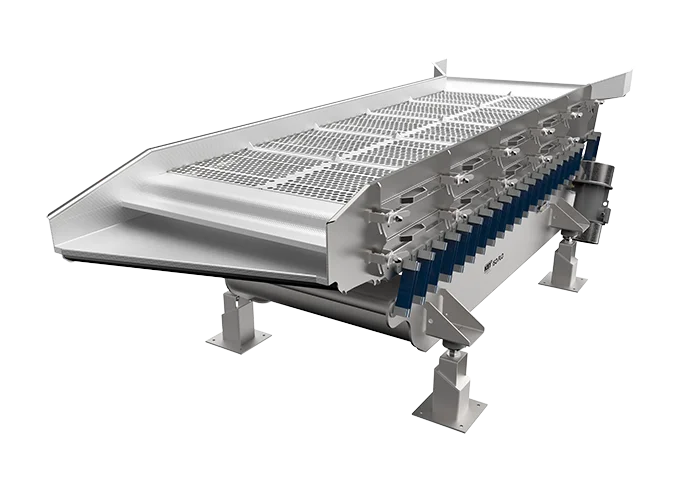

Key's tailored food handling systems move, align and distribute food products efficiently along high throughput processing lines with precise control, improving efficiency and maximizing yield.

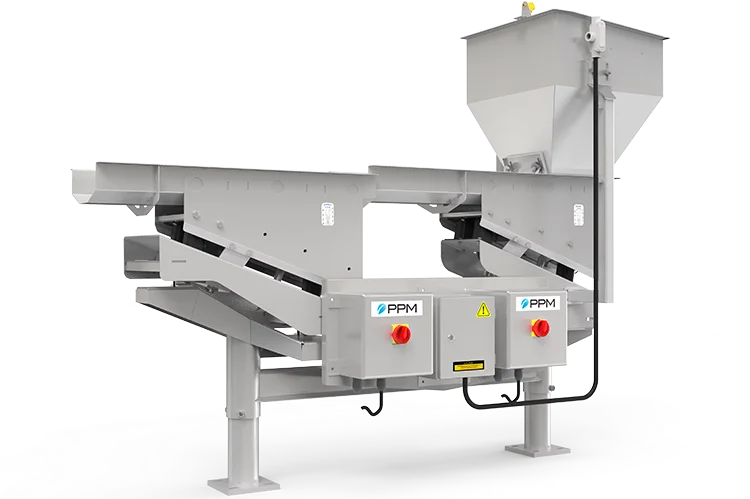

With precise control and high throughput, PPM’s vibratory conveyors handle even the most fragile products gently, ensuring safe and efficient distribution throughout the processing line.

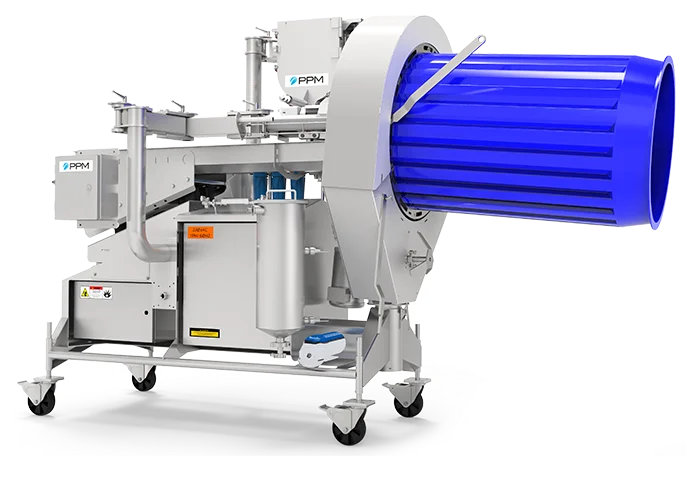

PPM's seasoning and coating equipment delivers consistent, even coverage while protecting product integrity—helping processors enhance flavor, texture and appearance of foods.

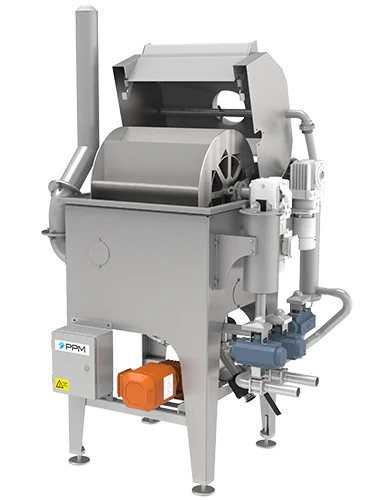

With uniquely efficient heating systems and advanced filtration technology, PPM's industrial fryers are designed to protect oil quality, reduce downtime and save operating costs.

Our systems deliver speed, freshness retention, and protection for fast-paced bakery and snack environments. We bring together nVenia’s weighing and filling, Mespack’s flexible packaging equipment, Pattyn’s bag-in-box, and Wulftec’s stretch wrapping.

From net weigh scales and multihead weighers to industrial sewing systems and sealers, nVenia provides solutions that ensure accuracy and integrity in every package.

Mespack provides innovative automation solutions for flexible pouches, sachets, stick packs, water-soluble pods, and end-of-line case packing—maximizing efficiency while supporting sustainable packaging technologies.

nVenia's rotary bagger and multiweighing technologies provide accurate weighing, filling and sealing of premade flat or stand-up pouches, ensuring efficient and quality packaging.

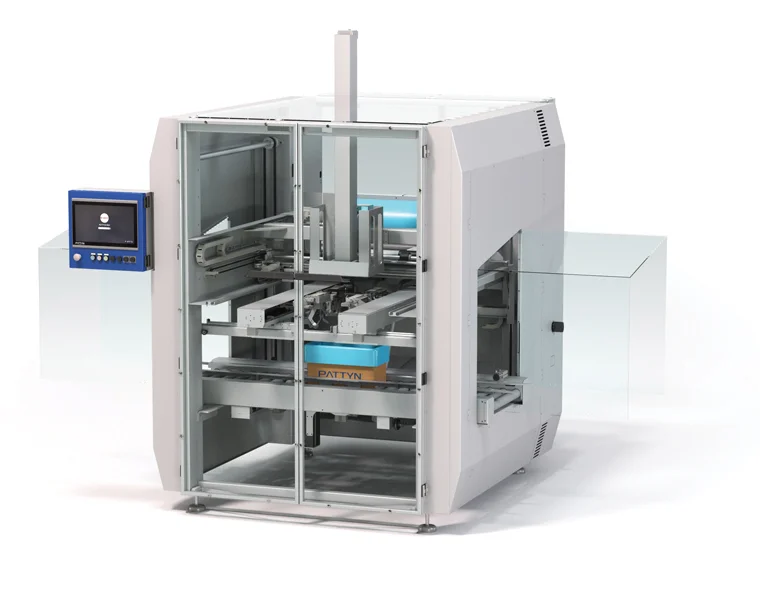

Pattyn’s bag-in-box systems combine turnkey automation with specialized 3D vision and robotics, handling everything from case erecting and bag inserting to filling, sealing, and end-of-line packaging for high-volume operations.

With semi-automatic and fully automatic options, Wulftec stretch wrappers provide robust, fully customizable solutions for secure product containment and pallet handling.

From QC Conveyors’ sanitary systems to FMH’s flexible conveyors, our solutions provide the hygienic design and gentle handling necessary to maintain product quality in high-speed bakery and snack operations.

QC’s HYDROCLEAN conveyors feature a configurable design and hold NSF and BISSC certifications, guaranteeing compliance with the highest sanitation standards in food, beverage, and pharmaceutical environments.

FMH Conveyors builds highly durable, versatile, and reliable flexible gravity and powered roller conveyors that easily adapt to evolving production requirements.

As your end-to-end automation partner, we listen and solve, innovate and support — so that nothing stands in your way.

As your end-to-end automation partner, we listen and solve, innovate and support — so that nothing stands in your way.