Equipment Brochure

View the latest Duravant equipment brochure.

Solutions

Explore end-to-end automation solutions that increase efficiency, improve quality, and help businesses thrive.

Markets

Learn how we serve industries worldwide with automation expertise tailored to the unique needs of each market.

Our Brands

Explore Duravant’s family of operating companies, united by expertise, shared values, and integrated solutions

View the latest Duravant equipment brochure.

Services

Access a global network of experts delivering full lifecycle support, from installation to optimization.

View latest Duravant Lifecycle Services brochure.

Company

Learn how Duravant unites world-class brands and people to keep essential goods moving smarter, faster, and more reliably.

Explore the latest Duravant brochure.

Every cut counts. Every system delivers.

In protein processing, precision and performance are non-negotiable. Every meat and seafood operation faces relentless pressure to maintain the highest food safety standards while maximizing yields and throughput. We know excellence isn’t measured in efficiency alone. It’s measured in the trust consumers place in every product. That’s why we stand with you every step of the way, supporting you in delivering consistent texture, flavor and quality.

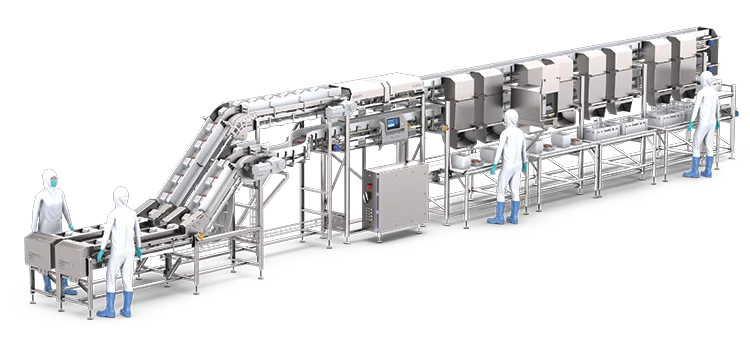

From Poss’s mechanical separators to Marelec’s portioning and grading systems, with Henneken’s vacuum tumbling and Marlen’s size reduction and thermal cooking, our systems maximize yields and throughput while ensuring food safety compliance for meat and seafood operations.

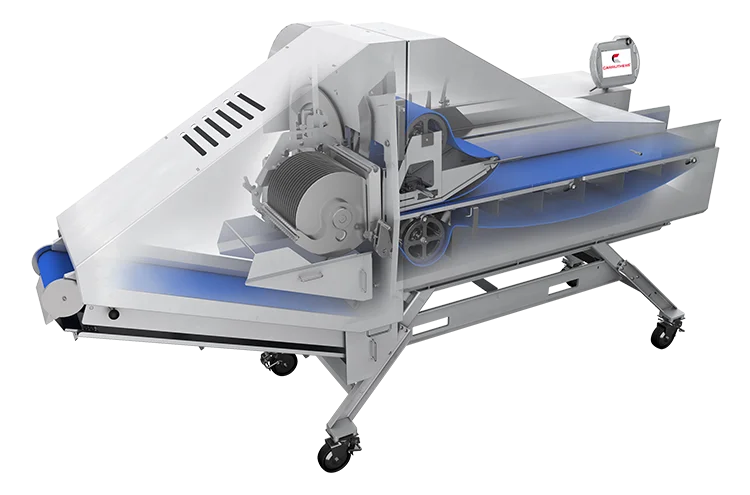

POSS mechanical separators provide efficient, high-yield recovery from meat, poultry and seafood trim, ensuring superior product quality with minimal waste.

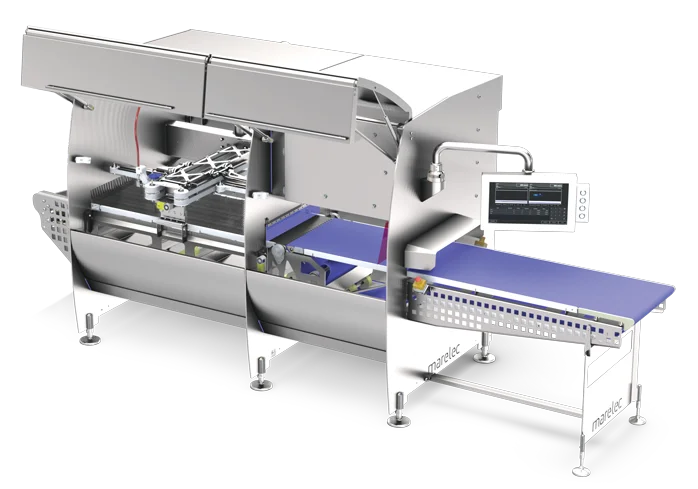

Precise and versatile portioning solutions from Marelec help processors maximize yield, ensure consistency and streamline cutting operations.

Marelec's weighing and grading solutions deliver unmatched accuracy, speed, and efficiency—helping processors maximize yield, reduce giveaway, and ensure consistent product quality.

Henneken injectors are engineered to deliver precise brine distribution, ensuring consistent flavor, texture, and product quality.

Henneken's vacuum tumblers enhance flavor, texture and yield by delivering uniform marination of meat, poultry and seafood products.

Marlen's slicers, dicers, and shredders consistently deliver superior cut quality and exact portion sizes across a wide range of products.

Marlen offers a full suite of searing, bar-marking, braising, roasting, and grilling solutions, ideal for producing consistent, high-quality results across diverse food products.

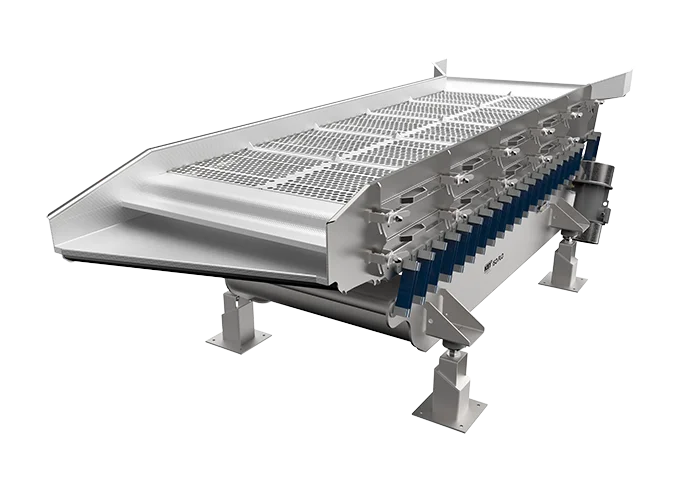

Gentle handling and quality assurance for raw and cooked products are delivered by Key’s processed foods optical sorting and vibratory conveying systems, maintaining high-speed processing while preserving texture, flavor, and presentation.

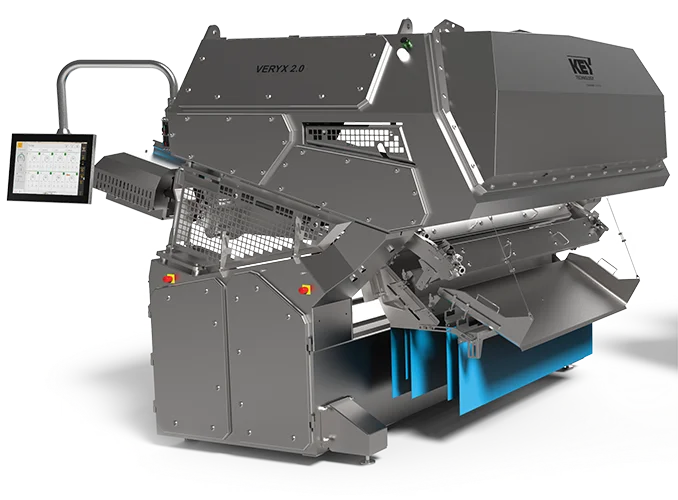

Key Technology delivers precise digital sorting with VERYX and COMPASS platforms that maximize yield and quality while providing real-time data analytics for continuous process optimization.

Key's tailored food handling systems move, align and distribute food products efficiently along high throughput processing lines with precise control, improving efficiency and maximizing yield.

From Mespack’s flexible packaging equipment and nVenia’s robotic palletizing, to Pattyn’s bag-in-box solutions and Wulftec’s stretch wrapping, our systems ensure quality presentation and waste minimization for meat and seafood operations.

Mespack provides innovative automation solutions for flexible pouches, sachets, stick packs, water-soluble pods, and end-of-line case packing—maximizing efficiency while supporting sustainable packaging technologies.

nVenia's rotary bagger and multiweighing technologies provide accurate weighing, filling and sealing of premade flat or stand-up pouches, ensuring efficient and quality packaging.

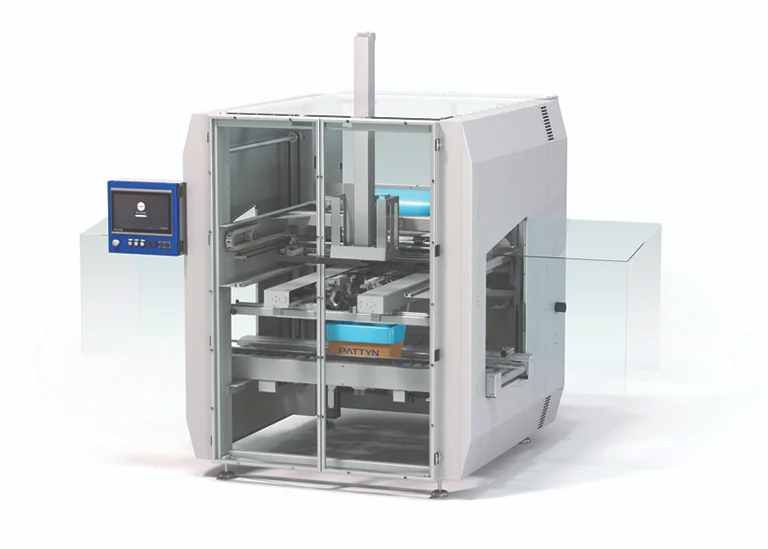

Pattyn’s bag-in-box systems combine turnkey automation with specialized 3D vision and robotics, handling everything from case erecting and bag inserting to filling, sealing, and end-of-line packaging for high-volume operations.

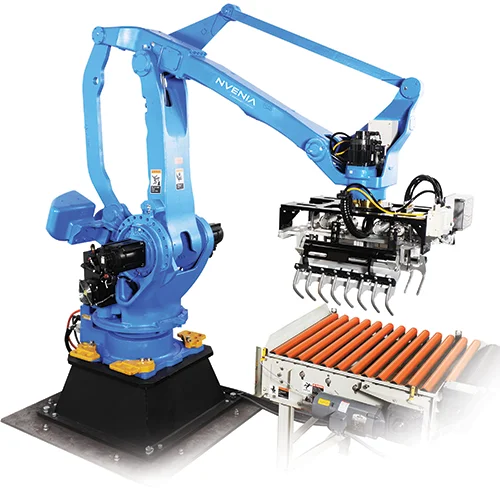

Engineered for durability, flexibility, and safety, nVenia’s fit-for-purpose robotic palletizing solutions help overcome labor challenges while maximizing efficiency.

With semi-automatic and fully automatic options, Wulftec stretch wrappers provide robust, fully customizable solutions for secure product containment and pallet handling.

Food safety and labor efficiency are delivered by QC Conveyors’ sanitary conveyors and FMH’s flexible conveyor systems, providing hygienic design that maximizes throughput while minimizing product damage and labor costs across meat and seafood processing facilities.

QC’s HYDROCLEAN conveyors feature a configurable design and hold NSF and BISSC certifications, guaranteeing compliance with the highest sanitation standards in food, beverage, and pharmaceutical environments.

FMH Conveyors builds highly durable, versatile, and reliable flexible gravity and powered roller conveyors that easily adapt to evolving production requirements.

As your end-to-end automation partner, we listen and solve, innovate and support — so that nothing stands in your way.

As your end-to-end automation partner, we listen and solve, innovate and support — so that nothing stands in your way.